|

|

|

Metal detectors for pipe

line installations -

PIPE LINE metal detection system is designed for inspection of

paste, minced meats, jam, slurry, sausage, baby food, soup, ice cream,

and liquid products in the pipe line system.

This unit is equipped in the latest control electronics type

ND-820 series, and rejection valve.

Several different sizes of are available to suit various

diameters of pipe line.

As the result of extensive research and development, this units

delivering impressive features and performance.

Inspecting on pipeline makes product effect smaller.

The pipe and automatic valve can be attached and detached easily for

cleaning.

Made of stainless steel for sanitary applications

- Pumping the products to the detector through pipe without

air gap, consequently "Product Effect" can be reduced.

- Detachable pipe/rejector(auto valve)

- Waterproof execution

- Applicable to minced meat, sausage, been jam, soup, etc.

Features

- High Metal Detection Sensitivity

High metal detection sensitivity 0.4 mm steel balls and 0.8 mm SUS304

balls.

- Easy Operation and Adjustment

1. Interactive Display

The large, easily legible display makes operability easy.

2. Automatic Sensitivity Setting

Simply by feeding a product through the detection unit several times

makes it possible to store the product characteristics in memory and

automatically set to the optimum sensitivity, thereby eliminating the

need for bothersome adjustment procedures.

(If required, manual adjustment is also available.)

3. Effect Automatic Tracking

The characteristics of a product (product effect) change due to changes

in product temperature and so forth. This function tracks these changes

and automatically keeps the most adequate setting at all times.

4. Setting of 200 Products

The characteristics of up to 200 products can be stored in memory in

accommodation of production lines handling a wide range of products.

Kind of products is displayed using product names.

- Improved Yield

The use of a search coil having a high level of vibration resistance

makes it possible to significantly shorten rejection time and reduce

the amount of rejected material.

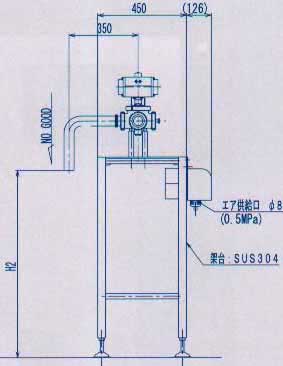

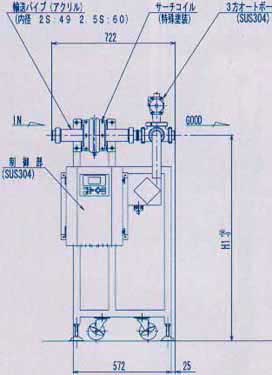

- Confined Space Installation

The Metal Detector and rejector are integrated into a single unit for a

compact design.

- Compatibility with External Communications

This function allows the detector to transmit data to related equipment

using an RS422 or RS232C interface (optional).

- History Display

Operation history can be confirmed in indicator.

The last 999 operations including power on/off, setting change, metal

detection, etc. are stored in memory with each time.

- In addition to the above, customized specification

meets with your requirement is also available.

Standard Specifications

|

MODEL

|

MD-800UV

|

| Diameter of transporting pipe:- |

2"

|

Detection sensitivity *1

Fe balls

SUS304 balls |

0.4 mm

0.8 mm

|

| Passing speed:- |

15 m./min

|

| After detection:- |

3 way auto valve rejector

|

| Power supply:- |

110/ 220 V AC, 50/60 Hz

|

| Weight Approx. :- |

70 kg

|

*1: These data show results of measurements at our factory.

Please note that actual detecting sensitivity depends on the product

characteristics and operation environment.

Complete turnkeys packaging solutions are available on request.

Please contact us on info@jzw.com.au to discuss your application.

|

Metal detector for pipeline

installation including reject system

Metal detector for pipeline

installation including reject system

ND-820UV metal detector for pipeline

installation including reject system

ND-820UV metal detector for pipeline

installation including reject system

|