|

|

|

Metal detector for iron

ore, minerals processing -

This detector prevents damage to equipment by detecting iron

piece contaminated in various ore using a detection method that

utilizes effect by iron loss.

- This metal detector uses a detection method that utilizes

the effects of iron loss to effectively detect iron piece contaminated

in all types of ores.

- The Search Coil (M type) is composed of a mono-frame coil,

eliminating the need for a coiling work at the installation site. In

addition, since this mono-frame coil is completely free of interference

caused by vibrations between each coil, it offers particularly superior

vibration resistance.

- The search coil can be easily removed from the conveyor,

enabling the amount of time required to install the search coil to be

shortened considerably as compared with conventional model.

- The rigid structure of the mono-frame search coil employs

completely water-resistant construction, resulting in a significant

reduction in deterioration of characteristics caused by changes over

time.

Standard Specifications

|

MODEL

|

|

| Applicable belt width:- |

900 - 2000 mm

|

| Applicable Aperture Height:- |

450 - 770 mm

|

| Power supply:- |

220 V AC, 50/60 Hz

|

| Allowable voltage fluctuation range:- |

-10% to +10%

|

| Construction:- |

Steel-plated, water-resistant construction

|

| Contact capacity:- |

220 V AC, 3 A (1ab, 1b)

|

| Power supply:- |

AC 220 V, 50/60 Hz

|

| Weight Approx. :- |

65 - 130 kg

|

Complete turnkeys packaging solutions are available on request.

Please contact us on info@jzw.com.au to discuss your application.

|

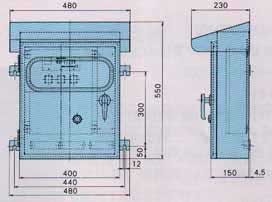

ND-172 metal detector for iron ore,

and minerals processing - control unit

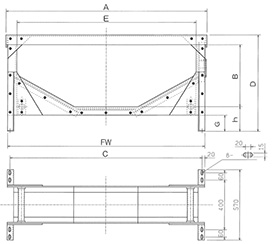

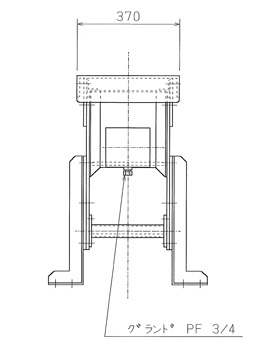

ND-172 metal detector for iron ore, and

minerals processing - search coil drawings

ND-172 metal detector for iron ore, and

minerals processing - search coil drawings

ND-172 metal detector for iron ore, and

minerals processing - control unit drawings

|