|

|

|

Metal detectors for

mining projects -

This detector is used to prevent damage to crushers, conveyor

belts and other machinery in advance by detecting iron piece

contaminated in crushed stone, ores, etc.

- ND-150D metal detector is used to detect metallic pieces

contaminated in crushed stone or limestone, etc. for preventing damage

to crushing machines and conveyor belts in advance.

- The Model ND-150D metal detector contains a special

built-in circuit that easily removes the effects of iron components

contained in product (crushed stone, etc.).

- In addition to being able to detect iron fragments, the

Model ND-150D metal detector is also capable of detecting non-ferrous

metal fragments that can not be attracted or removed with magnetic

separators. It functions particularly effectively for high-manganese

steel such as that in the claws of shovel loaders.

- The device integrates a control unit and search coil into

a single unit resulting in a compact design. In addition, it is

designed and manufactured to adequately withstand even outdoor use.

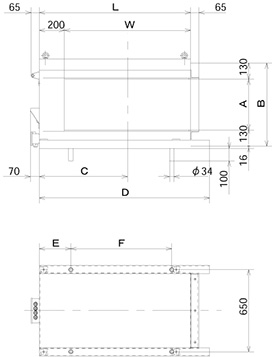

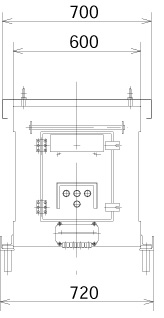

- installation of this type of metal detector is simple.

Mechanical installation require only four point attachment to the

conveyor frame. Electrical work consists of connecting only three

cables, including the power cable.

Standard Specifications

|

MODEL

|

|

| Applicable belt width:- |

400 - 1400 mm

|

| Applicable Aperture Height:- |

400 - 600 mm

|

| Power supply:- |

220 V AC, 50/60 Hz

|

| Allowable voltage fluctuation range:- |

-10% to +10%

|

| Belt speed:- |

30 m/min - 300 m/min

|

| Construction:- |

Steel-plated, water-resistant construction

|

| Contact capacity:- |

220 V AC, 3 A (1ab, 1b)

|

| Power supply:- |

AC 220 V, 50/60 Hz

|

| Weight Approx. :- |

140 - 200 kg

|

Complete turnkeys packaging solutions are available on request.

Please contact us on info@jzw.com.au to discuss your application.

|

ND-150D metal detector for mining

applications

ND-150D metal detector for mining

applications

ND-150D metal detector for mining

applications

ND-150D metal detector for mining

applications

|