|

|

|

Metal detection system

for powders and grains -

This detector can be installed in production lines handling

powders and row materials in the food industry, chemical industry and a

wide range of industries. This self contained metal detection system

includes rejection system. Combining with a Search Coil featuring

improved vibration resistance and a Control Unit results in superior

operating ease with high sensitivity.

- High Metal Detection Sensitivity

- Easy Operation and Adjustment

1. Interactive Display

The large, easily legible display makes operability easy.

2. Automatic Sensitivity Setting

Simply by feeding a product through the detection unit several times

makes it possible to store the product characteristics in memory and

automatically set to the optimum sensitivity, thereby eliminating the

need for bothersome adjustment procedures.

(If required, manual adjustment is also available.)

3. Effect Automatic Tracking

The characteristics of a product (product effect) change due to changes

in product temperature and so forth. This function tracks these changes

and automatically keeps the most adequate setting at all times.

4. Setting of 200 Products

The characteristics of up to 200 products can be stored in memory in

accommodation of production lines handling a wide range of products.

Kind of products is displayed using product names.

- Improved Yield

The use of a search coil having a high level of vibration resistance

makes it possible to significantly shorten rejection time and reduce

the amount of rejected material.

- Confined Space Installation

The Metal Detector and rejector are integrated into a single unit for a

compact design.

- Fine powder can be rejected

Improved sealing function of rejector doesn't occur the product leak

when rejection.

- Compatibility with External Communications

This function allows the detector to transmit data to related equipment

using an RS422 or RS232C interface (optional).

- Can save the history data and settings to a USB

memory, it can also be output to a dedicated printer.

- History Display

Operation history can be confirmed in indicator.

The last 999 operations including power on/off, setting change, metal

detection, etc. are stored in memory with each time.

- In addition to the above, customized specification

meets with your requirement is also available.

Standard Specifications

|

MODEL

|

MS-2242-100

|

MS-2242-150

|

| Pipe effective diameter:- |

77 mm

|

125 mm

|

| Product to be checked:- |

various grains and powders

|

| Transport capacity:- |

7 t/h *1

|

20 t/h *1

|

Max. sensitivity*2

Fe balls

SUS304 balls:- |

0.7 mm

1.5 mm

|

1.0 mm

2.5 mm

|

| Max. Passing speed:- |

Free-fall from 1500mm above flange of detector

(Approx. 350m/min.)

|

| After detection:- |

Air dumper type rejector

|

| Power supply:- |

AC 220 V, 50/60 Hz

|

| Weight Approx. :- |

75 kg

|

*1*2: This value is measured with plastic pellet.

Complete turnkeys packaging solutions are available on request.

Please contact us on info@jzw.com.au to discuss your application.

|

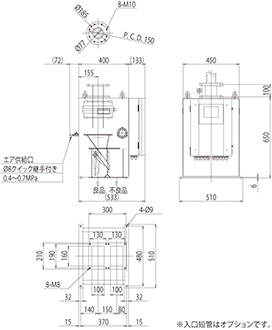

MS-2242 metal detection system for

powders and grains with integrated rejector

MS-2242 metal detector for powders and

grains

|